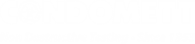

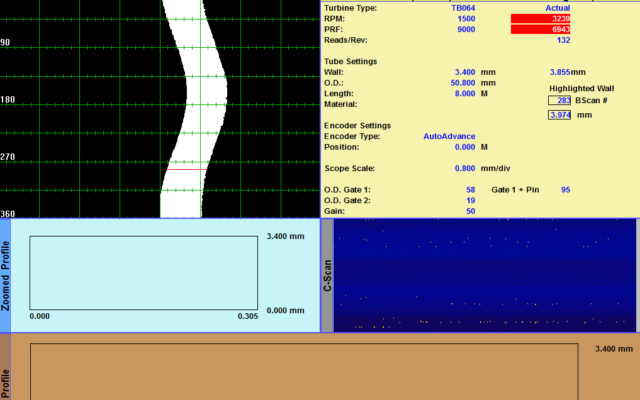

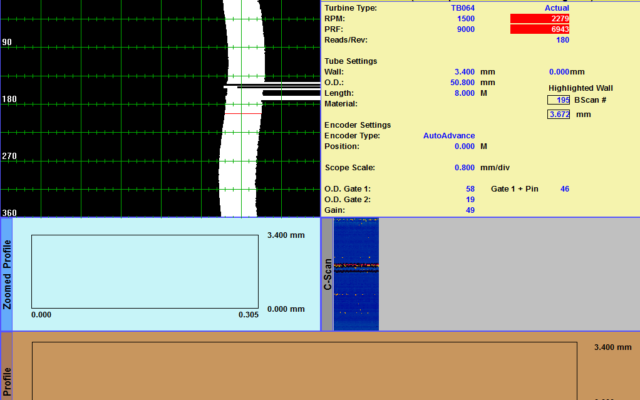

Iris inspection is performed on ferrous, non-ferrous and non-metallic tubes and through an ultrasonic transducer array with rotating head running inside the tested tube.

This technique detects any possible wall reduction caused by corrosion, erosion, wear, pitting and flaking; wall thickness results from the interval time between the first and the second echo.

One of the main Iris advantages is the immediacy of the result.