A coil of conductive wire is excited with an alternating electrical current. This wire coil produces an alternating magnetic field around itself. The magnetic field oscillates at the same frequency as the current running through the coil. When the coil approaches a conductive material, currents opposed to the ones in the coil are induced in the material — eddy current.

Variations in the electrical conductivity and magnetic permeability of the test object, and the presence of defects causes a change in eddy current and a corresponding change in phase and amplitude that can be detected by measuring the impedance changes in the coil, which is a telltale sign of the presence of defects.

ET has a very wide range of applications. It allows any kind of application related to variations of chemical and physical characteristics of any conductor. In other terms, it is possible to detect the slightest discontinuity of a material (geometric, electric or magnetic).

Here are some advantages of eddy current inspection:

- sensitivity to small cracks or lacks

- detection of surface or lower layer lacks

- immediate result of the inspection

- portable equipment for great versatility

- a minimum preparation of the item to be tested is required

- it is possible to detect complex items of different sizes and dimensions

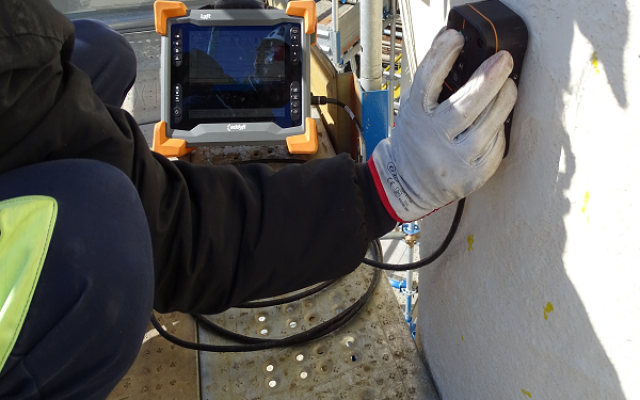

LYFT

This instrument can measure thickness without lifting insulation (liftoff) and gives real-time C-scan images, a quick data acquisition (up to 15 readings per second) through dynamic scanning and grid mapping. Scanning can be performed on thick metal and insulation, as well as on aluminium, stainless or galvanized steel.

Lyft can be used also for: corrosion under insulation (CUI), corrosion blistering and scabs, flow-accelerated corrosion (FAC), corrosion under fireproofing (CUF), corrosion under paint.